Training Course for the Project Counterpart (Country-Focused Training) in Japan 2024

The counterpart training in Japan was conducted in August and September 2024, inviting six Noguchi Memorial Institute for Medical Research (NMIMR) staff including biomedical engineers, Mr. Clement Bridjoe and Mr. George Hansen; electrical engineers, Mr. Romulus Ocansey and Mr. Augustine Mintah; and safety officers, Mr. Felix Kwame Zoiku and Ms. Nanabea Akuffo-Lartey to strengthen the capacity for safety and quality management.

The first training took place in July 2023, and this is the second one. This year’s training is especially focused on the management of facility and biomedical equipment for engineers and safety management, including high containment facility for safety officers. Based on the lessons learned from the previous year, the Project started the planning and coordination of the training early, interviewing the participants about what they wanted to take away to home countries as the outcomes of the training. After conducting the problem analysis in their workplace, the participants established their objectives and action plan for the training beforehand. They also shared this information with the tutors of the training from Japanese companies, enabling them to tailor the training to the participants’ needs. Some programs of the training were conducted with the participants from the Philippines and Zambia, where JICA is implementing projects similar to the Project in NMIMR.

The training began on 26th August with an opening ceremony and course orientation, followed by the visits to the National Institute for Infectious Diseases (NIID) for lectures on biorisk management and an overview of BSL-3 facilities, which provided a comprehensive understanding of managing biosafety risks in high-containment labs. (pic 2)

Thereafter, they were divided into groups to focus on themes in their respective expertise. Two safety officers, together with participants from Zambia and the Philippines, were immersed in a series of lectures, facility tours, and hands-on sessions that provided them with a deep understanding of Japan’s advanced practices in biorisk management, including BSL 3 lab management, sample management, quality control, equipment management, 5S in the lab, risk communications etc. (pic 3)

Biomedical engineers visited various manufacturers to obtain deeper understandings of the high-end biomedical equipment, preventive maintenance and troubleshooting of the equipment through hands-on practices. (pic4, 5)

Electrical engineers were trained in facility management, especially by the consultants who joined the construction process of Advanced Research Laboratories (ARL). The engineers shared various challenges they had faced during the maintenance after the ARL was handed over to NMIMR in 2019. (pic 6)

This training was designed to address the actual problems/challenges directly to overcome for solutions. The training was meaningful not only for the participants but also the stakeholders who had been involved in the construction process to understand the real situation on the ground after handing over the ARL.

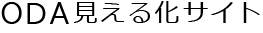

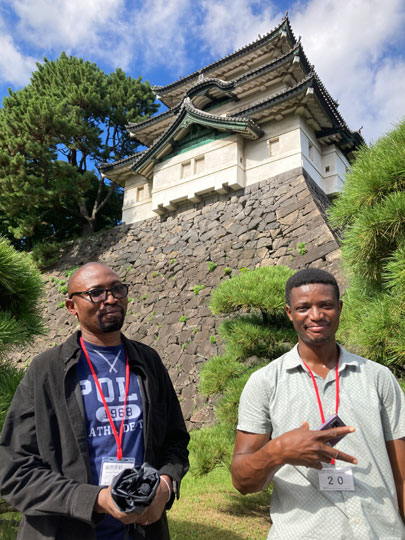

Safety officers spent only two weeks in Tokyo; it was a quite busy schedule for them, but they enjoyed Japanese culture, food and meeting Japanese people. Engineers were given opportunities to appreciate Japan’s cultural heritage such as the Imperial Palace during their stay for four weeks. (pic 7)

They are now expected to implement some action plans to improve in quality and safety in NMIMR. The training gave the participants the opportunity to share their experiences, discuss similar challenges in the different countries and create the network of trainees for future cooperation. The participants expressed great appreciation for it.

The following companies and organizations who supported and provided the training are highly appreciated, and the Project hopes further assistance and communications to the participants for implementation of their action plans. (pic 8)

Biomedical Equipment Engineering Team

EVIDENT CORPORATION, IKARI SHODOKU CO., LTD., JAPAN, LIFE TECHNOLOGIES JAPAN CORPORATION, SHIMADZU CORPORATION, SYSMEX CORPORATION, TAKARA BIO INC., TECAN JAPAN, TOMY DIGITAL BIOLOGY CO., LTD., YAMATO SCIENTIFIC CO., LTD., METTLER TOLEDO INTERNATIONAL INC.

Electrical Engineering Team

AZBIL CORPORATION, NIHON SEKKEI CO., LTD., OSAKADENKIKOGYO CORPORATION, SAKURA SEIKI CO., LTD, SINRYO CORPORATION, IKESHITA BIM INSTALLATION CO.,LTD.

Biosafety and Security Team

AIRTECH JAPAN, LTD., BECKMAN COULER INC, MICROSKY LAB.INC., H.U. GROUP HOLDINGS, INC., TRES COUNSERING COOPERATION, WASEDA UNIVERSITY, NATIONAL CENTER FOR GLOBAL HEALTH AND MEDICINE(NCGM).

Overall Training Programme and Implementation

NATIONAL INSTITUTE FOR INFECTIOUS DISEASES (NIID), JAPAN ANTI-TUBERCLOSYS ASSOCIATION (JATA).

Visit to NIID Toyama Research Laboratories

Safety officers learned how equipment works at Beckman Culter, Inc.

Biomedical Engineers learned High-performance liquid chromatography (HPLC) at SHIMADZU CORPORATION.

Biomedical engineers learned safer fumigation procedure at IKARI SHODOKU CO., LTD.

Electrical Engineers had a boiler maintenance training for a double-door giant autoclave.

Engineers visited the Imperial Palace.

Engineers received the certification at the end of the training.