We are delighted to announce that a seminar and demonstration on Hokuryo's Cutting Machine, co-organized by Hokuryo, Nihon Suido Consultants and RDG Supply, will take place at the Indah Water Konsortium (IWK) Training Center under JICA SDGs Business supporting Survey (JICA Biz).

This event aims to bring together Cured-in-Place Pipe (CIPP) and Closed-Circuit Television (CCTV) contractors in Malaysia, along with IWK, to explore the innovative solutions offered by Hokuryo's cutting machine. This event offers valuable insights into cutting-edge technology and techniques for sewer maintenance and rehabilitation.

Event details:

Date: 5th of June (Wed), 2024

Time: 9:00 -11:30 am

Venue: Indah Water Training Centre (IWTC), Sg. Besi Regional Sewage Treatment Works, Lot 33519, Bukit Jalil, KL-Seremban Highway, 57000 Kuala Lumpur.

Agenda:

- Introduction of Hokuryo's cutting machine

- Demonstration of making holes for lateral connections using Hokuryo's cutting machine

- Demonstration of removal of failed lining material from sewer pipes using Hokuryo's cutting machine

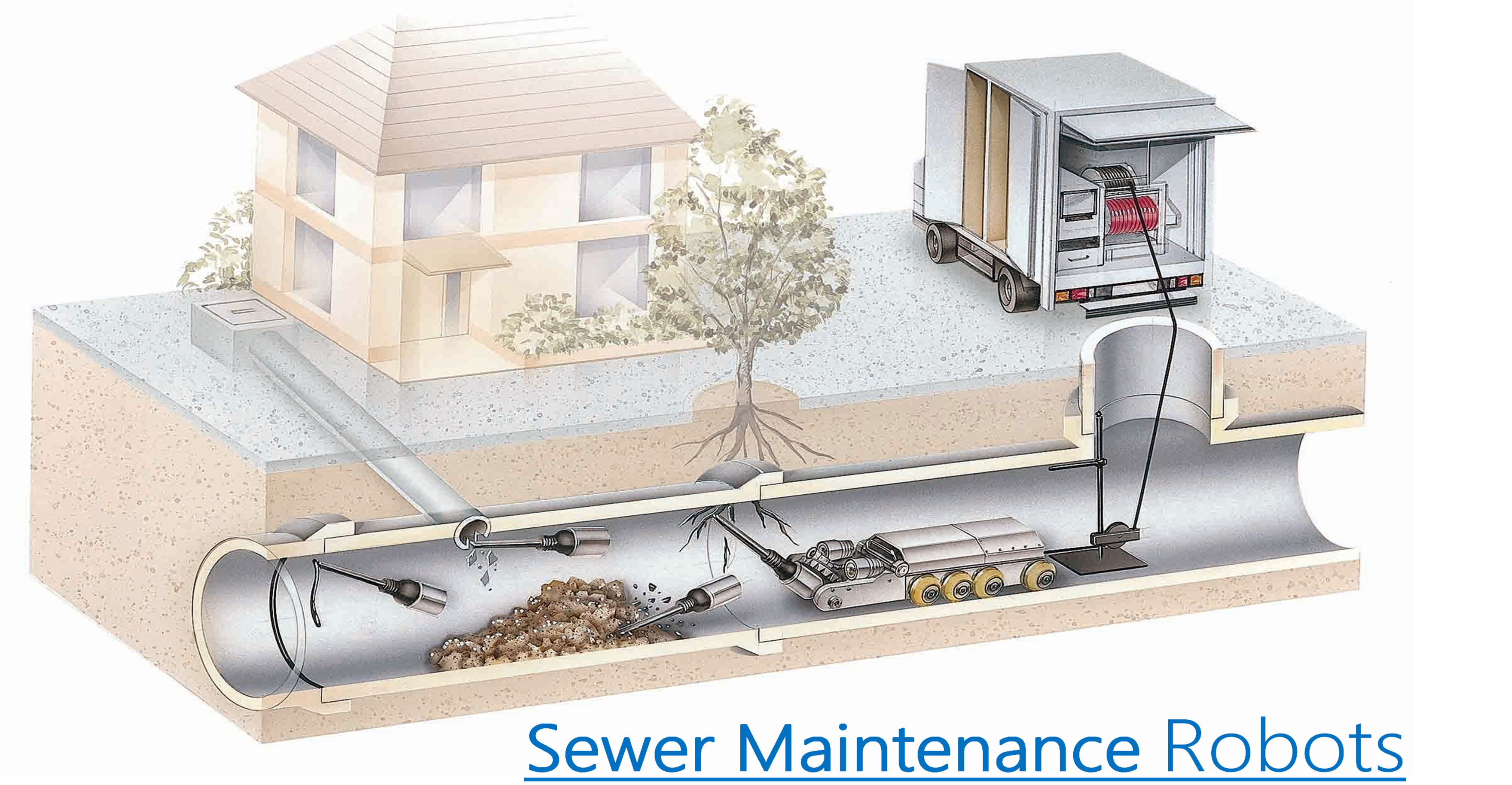

- Scheme

SDGs Business Verification Survey

-

Project Name

Operation &Maintenance by Sewer Maintenance Robots in Malaysia

-

Project Duration

December 2021 – August 2024

-

Contracting party

Hokuryo Co., Ltd.

-

Background

The Malaysian government aims to extend sewerage connection more than 80% population equivalent in urban areas. On the other hand, sewer overflows and pipe collapse are frequently occurred due to damage of sewer pipes and sewer blockages. Existing sewer pipes in Malaysia are suffering from damage due to aged deterioration, corrosion, poor construction of the joint part, tree roots, oil and garbage, and blockage due to construction materials such as mortars, etc.

-

Objectives

The effectiveness and superiority of the Hokuryo’s Maintenance Robots in rehabilitation works and daily maintenance of sewer pipes are verified through a demonstration experiment in Malaysia.

The proper sewer pipe management is promoted through capacity buildings for IWK.

The business development plan for the Hokuryo’s Maintenance Robots is prepared.

-

Outputs

Output 1: The sewer pipe rehabilitation works using the Hokuryo’s Maintenance Robots are properly implemented, and its effectiveness and superiority are verified.

Output 2: The daily maintenance of sewer pipes using the Hokuryo’s Maintenance Robots is properly implemented by IWK, and the improvement of sewer pipe management capacity of IWK is confirmed.

Output 3: The business development plan for the Hokuryo’s Maintenance Robots is prepared.

- Information of the Sewer Maintenance Robots

The sewer maintenance robots,

Super Mini-Mogu, can make holes for house connections with sewer pipes after pipe rehabilitation works by lining method. It can also remove obstacles for sewer pipes with dia. 600 mm or less, such as intrusion of roots of trees, adhesion of mortars, etc. It has following advantages:

- High specification (high rpm and 360° head rotation)

- High durability and low price (cost effective)

- Simple structure and lightweight

- Easy operation and handling

- Environmental friendly design utilizing air motor

For further information, please contact:

JICA Malaysia Office,

Mr. Zenjiro EGAWA

E-mail: egawa.zenjiro2@jica.go.jp

Tel:+60-3-2166-8900

(

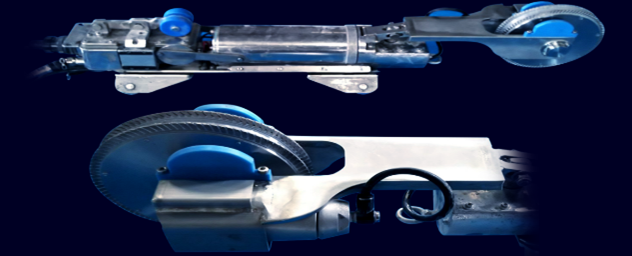

Pix below):

Liner Removal Machine, can remove rehabilitation material (= liner) from rehabilitation pipes (after completion of rehabilitation lining work). A general engine-type compressor is used to cut the liner at a pressure of 0.7Mpa. The thickness of reclaimed wood that can be cut is 5mm to 10mm. It can be used in conjunction with Super Minimog, but a separate investigation camera robot is required.

【Compatible Pipe Diameter】200-600mm 【Main Cable】70m 【Specifications】No camera

scroll