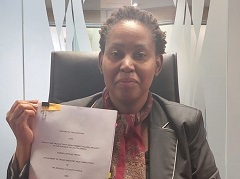

Signing of Record of Discussions on Technical Cooperation Project with South Africa: Support for Quality and Productivity Improvement of Enterprises through KAIZEN

2022.04.13

On March 28, the Japan International Cooperation Agency (JICA) signed a Record of Discussions with the Government of the Republic of South Africa in Pretoria for the Quality and Productivity Improvement (KAIZEN) Project, a technical cooperation project.

“KAIZEN” is a general term given to a number of unique techniques and tools that were evolved in Japan to improve the quality and productivity of enterprises, which in turn supported Japan’s rapid economic growth, expanding outward from the production sites of the manufacturing industry. JICA has been promoting KAIZEN by working on developing human resources and increasing organizational capacity in more than 30 countries so far*.

JICA dispatched an “Automotive Industry Human Resources Development Advisor” (2017-2020) to South Africa to foster consultants who provide automotive parts manufacturers with QPI (Quality and Productivity Improvement) training.

Leveraging such prior development and training efforts, this new project aims to create a mechanism that will continuously spread QPI activities in more than three provinces, as well as in several sectors such as automotive, metal fabrication and the service industry. It plans to build a network connecting business-support organizations, industry associations, and academic institutions, etc. The project is also designed to enhance human resources development and to implement the necessary system for providing sustainable QPI training and promotion activities, with the goal of improving the quality and productivity of small and mid-sized enterprises as well as strengthening their competitiveness. The project will contribute to the achievement of SDGs Goal 8 (Decent work and economic growth) and Goal 9 (Industry, innovation and infrastructure).

(*)“KAIZEN” is characterized by first changing the mindsets of managers and workers, promoting teamwork, and enhancing communication, and then disseminating these benefites to the whole company using a continuous approach, while utilizing tools such as 5S, 7QC, and TQM.

For further information, see the “KAIZEN HANDBOOK (Summary)”

| Country | Republic of South Africa |

|---|---|

| Project title | Quality and Productivity Improvement (Kaizen) Project |

| Planned implementation period | 60 months |

| Executing agency | Department of Trade, Industry and Competition Industrial Competitiveness and Growth Branch |

| Target region | The Project will be implemented nationwide, mainly in Gauteng Province, KwaZulu-Natal Province, and the Eastern Cape Province (tentatively). The selection of the provinces will be finalized based on the target areas of the target sectors. |

| Specific project details (provisional) | The project will create a sustainable mechanism to support corporate quality and productivity improvement and competitiveness enhancement in collaboration with business-support organizations, industry associations, and academic institutions, etc. By developing human resources via QPI (KAIZEN) training and carrying out activities to promote and spread the KAIZEN ethos, this project also aims to expand QPI activities nationwide. |

scroll