- Home

- Technical Cooperation Projects

- Index of Countries

- Africa

- Ethiopia

- Project on Capacity Development for KAIZEN Implementation for Quality and Productivity Improvement and Competitiveness Enhancement

- Project News

- Fourth Batch Intermediate-level Kaizen Implementation attained nearly 50% improvement in Kaizen Indicators

Project News

2019-07-26

Fourth Batch Intermediate-level Kaizen Implementation attained nearly 50% improvement in Kaizen Indicators

JICA's Kaizen Project (2015-2020) has been fostering Kaizen consultants who are able to provide intermediate-level Kaizen training and consulting services for the manufacturing industry and service sector. As of the 3rd batch training, 50 Kaizen consultants were trained, 45 from the Ethiopian Kaizen Institute (EKI), three from Addis Ababa City Kaizen Institute and two from Dire Dawa Management and Kaizen Institute. All the trainees of the 4th batch are from EKI, each with a social science background, such as economics, management, logistics, and not with an engineering background, which was previously the case.

The training of this batch began in January 2019 and just completed at the end of July. The training included a six-month In-Company Training (ICT) component, where each of the 19 trainees implemented Kaizen activities with assigned companies to improve the quality, productivity, cost and delivery in manufacturing process.

The Final Progress Sharing Meeting was organized by EKI, on July 25-26, at EKI. The purpose of the meeting was to confirm the result of the implementation of Kaizen activity in the last six months; and to discuss the way forward. The invited stakeholders such as ICT company representatives, Ministry of Trade and Industry (MoTI) and its Industrial Development Institutes (IDIs) such as MIDI, TICI, LIDI and CCIDI attended this meeting. There were presentations from the 19 trainees to share the Kaizen implementations and results in the 10 ICT companies. The Kaizen members of the companies also actively shared their experience on the occasion.

What should be noted in this batch is the average Kaizen Indicator (KI) , which shows the improvement rate before and after Kaizen, reached 49%. This shows that Kaizen interventions improved the companies' target such as quality and productivity by nearly 50%. This is the highest score compared to the previous three batches, which were 34%, 30% and 44%.

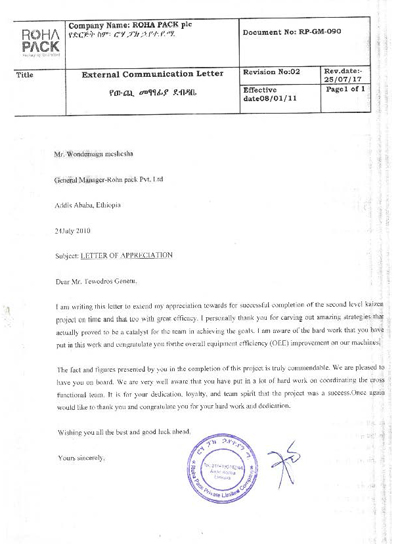

As a token of the efforts of trainees, one of the 10 companies, Roha Pack PLC (manufacturing PET preforms and bottles), provided a letter of appreciation to Mr. Tewodros Genetu, one of the 4th batch trainees in the meeting. He had worked with the company's Kaizen members to improve the Overall Equipment Effectiveness (OEE) of blow and mold machine. The OEE improved from 32% to 62% though the process of Kaizen, such as cause analysis, designing and implementation of the countermeasures and standardization. The representative of the company said that we will continue to work on Kaizen based on the experience we had together with Mr. Tewodros on the occasion of the Meeting.

TPS's Kanban session in classroom training in Jan. 2019

TPS's Kanban session in classroom training in Jan. 2019

Visit to Metal Industrial Development Institute (MIDI) in Feb. 2019

Visit to Metal Industrial Development Institute (MIDI) in Feb. 2019

Presentation of Mr. Tewdros Genetu during 3rd Progress Sharing Meeting at Debrezeit, June 2019

Presentation of Mr. Tewdros Genetu during 3rd Progress Sharing Meeting at Debrezeit, June 2019

Appreciation letter from Roha Pack PLC.

Appreciation letter from Roha Pack PLC.

- About JICA

- News & Features

- Countries & Regions

- Our Work

- Thematic Issues

- Types of Assistance

- Partnerships with Other Development Partners

- Climate Change / Environmental and Social Considerations

- Evaluations

- Compliance and Anti-corruption

- Science and Technology Cooperation on Global Issues

- Research

- JICA Development Studies Program / JICA Chair

- Support for the Acceptance of Foreign HRs / Multicultural and Inclusive Community

- Publications

- Investor Relations